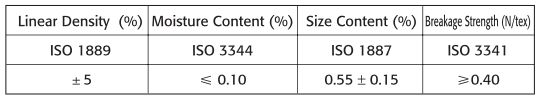

Technical Parameters

Mechanical Properties

Mechanical Properties

The above data are actual experimental clues for EDR24-2400-386 and for reference only.

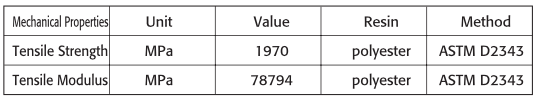

Storage

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15C~35C and 35%~65% respectively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, care should be taken to correctly and smoothly move the top pallet.

Packaging

*The product can be packed on pallet or in small cardboard boxes.

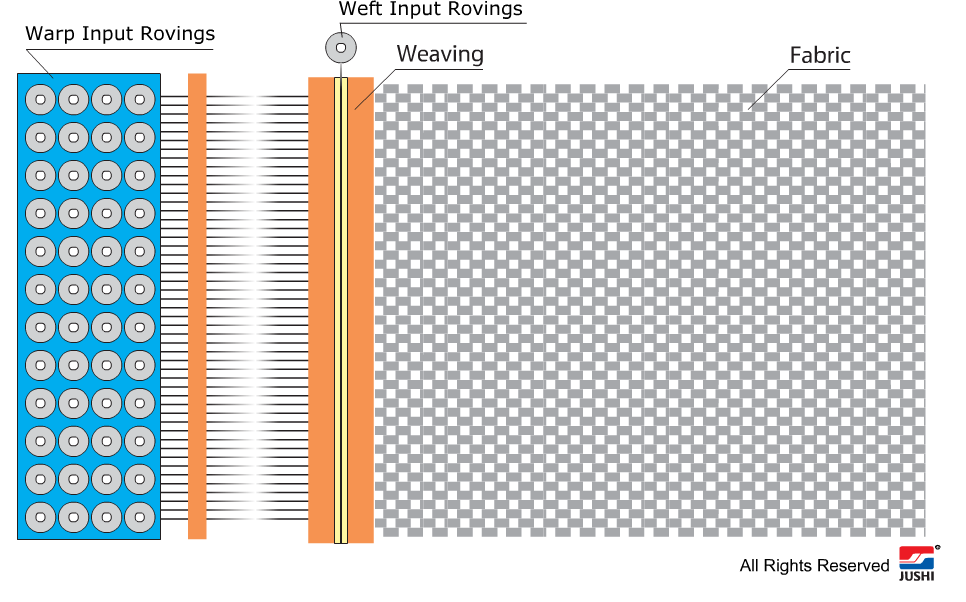

Weaving Process

Weaving is the process of making cloth, rugs, blankets, and other products by crossing two sets of threads over and under each other.

Weaving is the process of making cloth, rugs, blankets, and other products by crossing two sets of threads over and under each other.

Woven roving is a term generally used to describe heavy fabrics made by the weaving of fiberglass rovings.

Various weave patterns and weaving input combinations are possible.