Technical Parameters

Storage

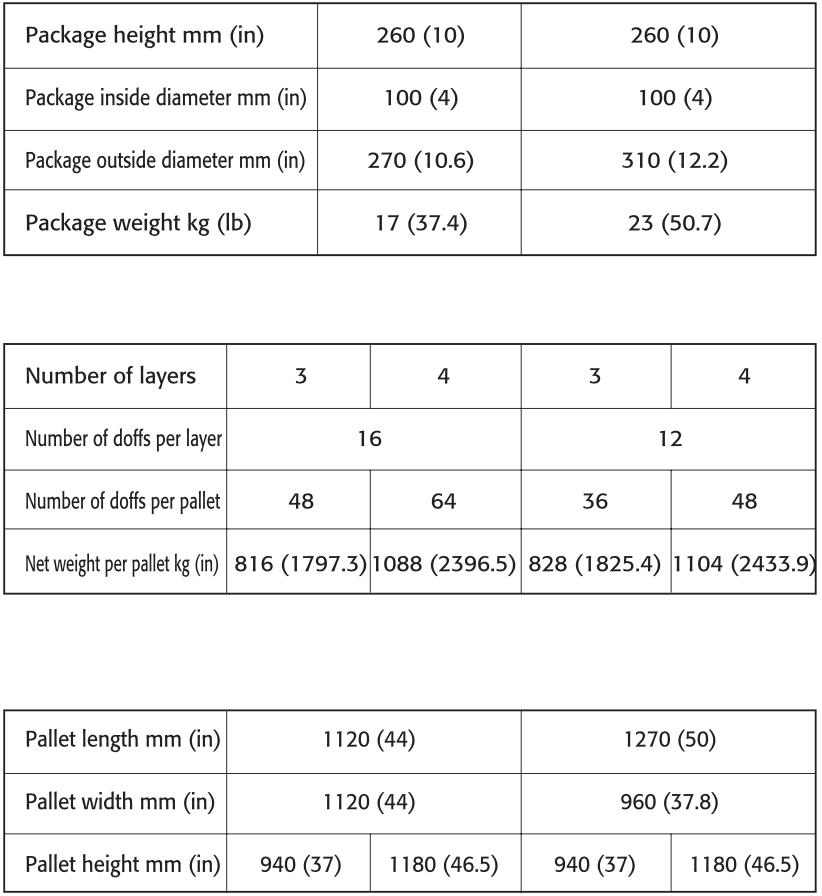

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15C ~35C and 35% ~65% respectively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, care should be taken to correctly and smoothly move the top pallet.

Packaging

* The product can be packed on pallet or in small cardboard boxes.

Spray-Up Process

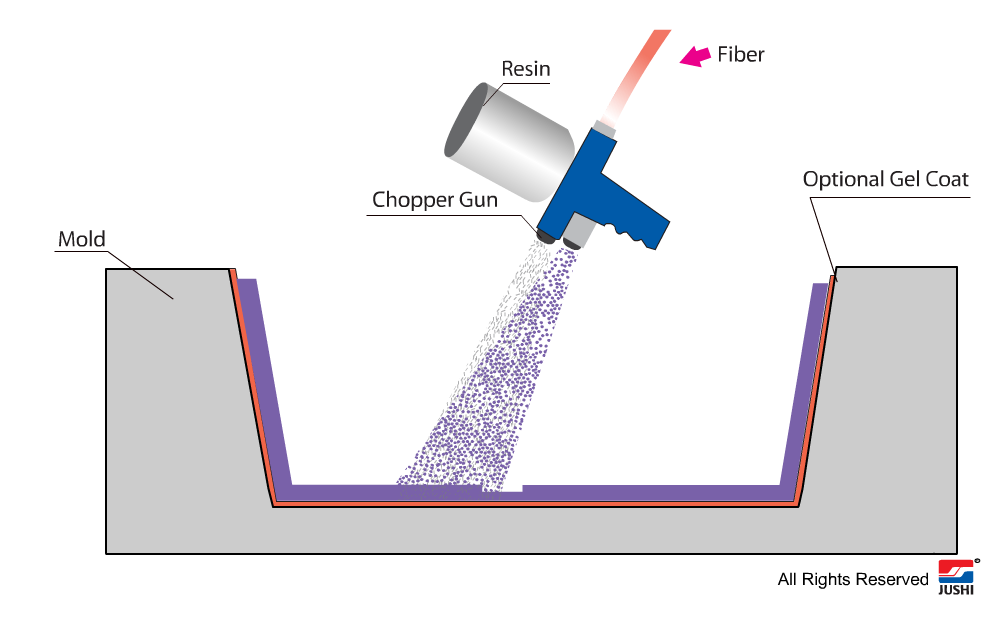

At the heart of the Spray-Up process is the spray or chopper gun, which simultaneously and uniformly chops the assembled roving, mixes it with the resin, containing initiator, accelerator, filler, pigment and other additives, and directs the mixed stream onto an open mold. The roving is chopped into a specific length. Compaction, wet-out and air-release are accomplished, using a roller as in the Hand Lay-Up process. One good appearance side is possible with this process. The material selection is important. The resin should be easy to atomize. The fiberglass roving should be of moderate stiffness, easy to chop, with good static and ribbon control, ensuring efficient processing.

At the heart of the Spray-Up process is the spray or chopper gun, which simultaneously and uniformly chops the assembled roving, mixes it with the resin, containing initiator, accelerator, filler, pigment and other additives, and directs the mixed stream onto an open mold. The roving is chopped into a specific length. Compaction, wet-out and air-release are accomplished, using a roller as in the Hand Lay-Up process. One good appearance side is possible with this process. The material selection is important. The resin should be easy to atomize. The fiberglass roving should be of moderate stiffness, easy to chop, with good static and ribbon control, ensuring efficient processing.