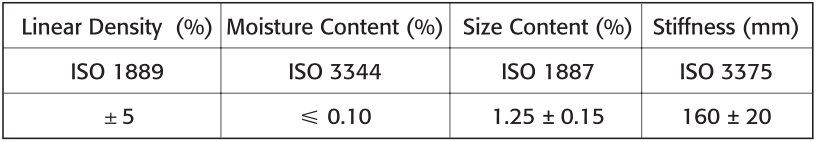

Techincal Parameters

Storage

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15 C ~ 35 C and 35%~65% respectively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, care should be taken to correctly and smoothly move the top pallet.

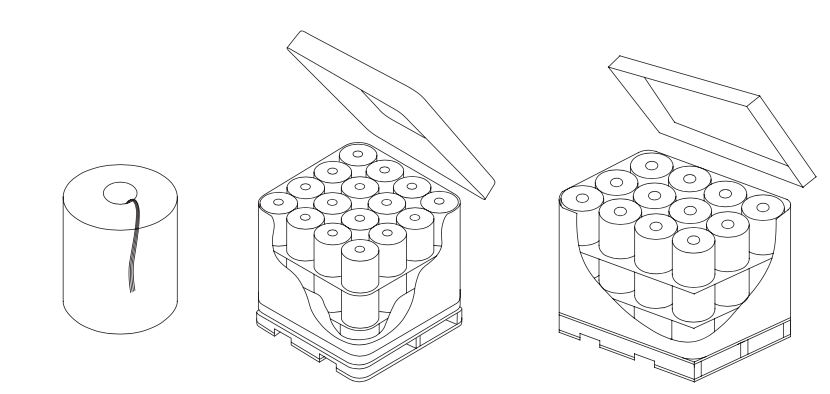

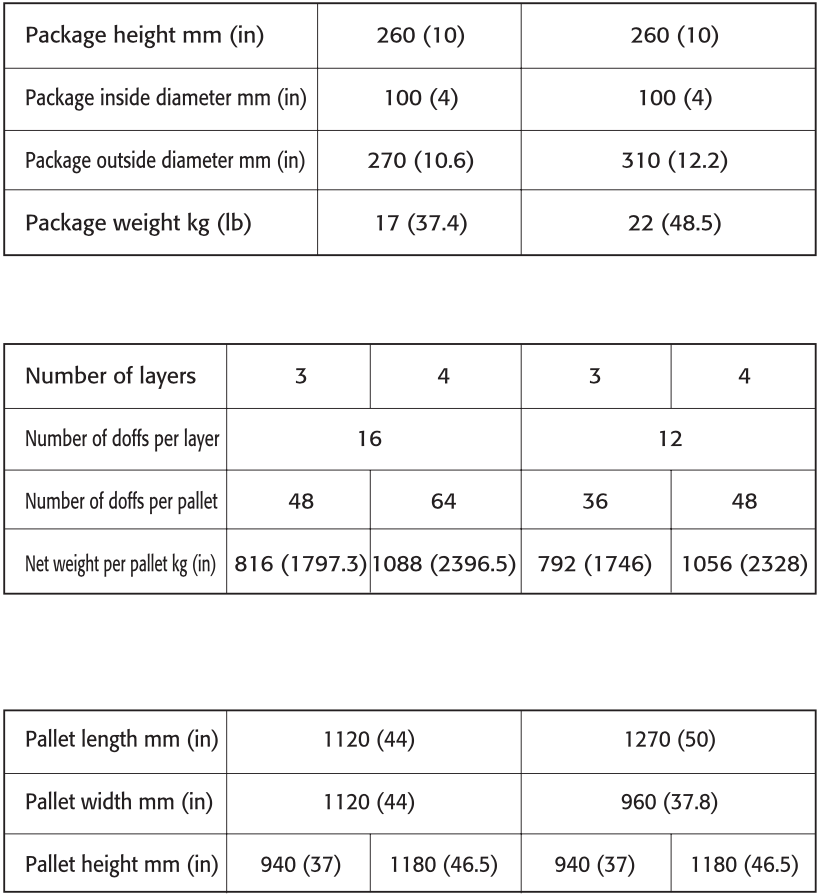

Packaging

*The product can be packed on pallet or in small cardboard boxes.

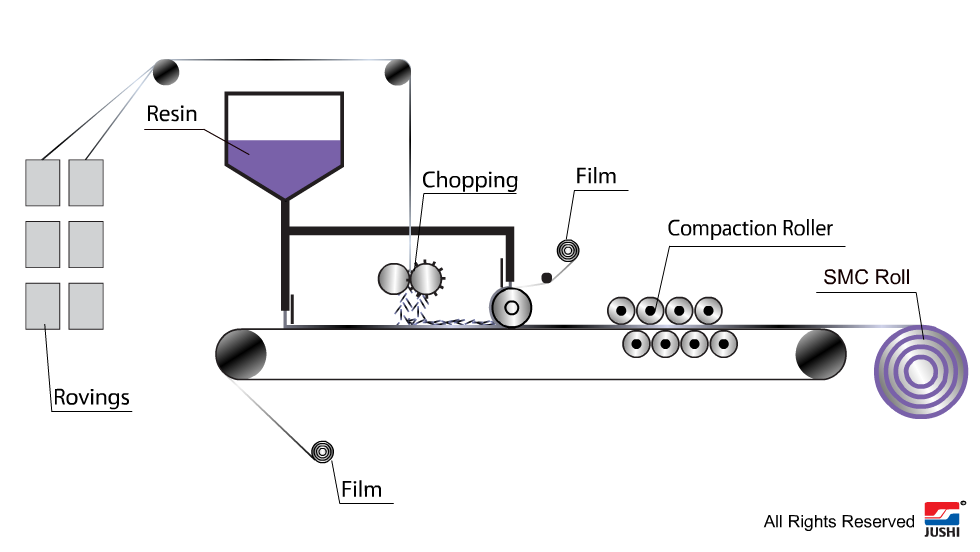

Sheet Molding Compound Process

.

Sheet Molding Compound(SMC) is a pre-preg combining random, chopped glass strands with filled polyester resin in the form of a sheet. Resin paste, containing resin (typically Unsaturated Polyester), fillers, thickener, catalyst, mold release and Low-Profile and other additives, is deposited on the bottom carrier film using a doctor-blade to precisely control the thickness. Assembled Roving, specifically designed for SMC, is chopped onto the resin paste film and covered by another top resin film. Thus formed sandwich is pulled through compaction section and either festooned into boxes or rolled up into large rolls. The thickening process, increase of the viscosity to a leather-like sheet, takes place in a moderate temperature maturation room. The SMC sheet is then easily cut into a charge during the Compression Molding of the final part. The low material cost of the SMC, largely due to high filler loading, and the efficiency of the Compression Molding result in low cost composite parts at mass production volumes. This makes SMC competitive in the automotive industry