Technical Specification

- Basis ISO/VE

- Density : 1.20 ± 0.05

- Viscosity : 13000-17000 cps

- Thixotropy : 5.5

- Reactivity : 200 gr mass – 2% PMEC 50 – 20°C 9 – 15 minutes (winter version)

- Gel time : 15 – 20 minutes (summer version)

Application

This product must be used at workshop temperature between 15 and 30°C.

No dilution is requested, only add the catalyst.

Catalyze: between 1.0 and 2.0 % of MEKP 50, according to the requested thickness and production cycle.

Homogenize the product before use.

Stop mixing before projection.

Check machine cleanness.

FSP-BC 1102 should be used on polymerized gelcoat “tacky”. Check that the product color changes after having catalyzed. Spray FSP-BC 1102 at about 70-80 cm from the support. Check regularly the sprayed thickness with a thickness gauge. The coat must be 500 to 800 microns.

Spray by doing crossed passes.

Please contact us for further information.

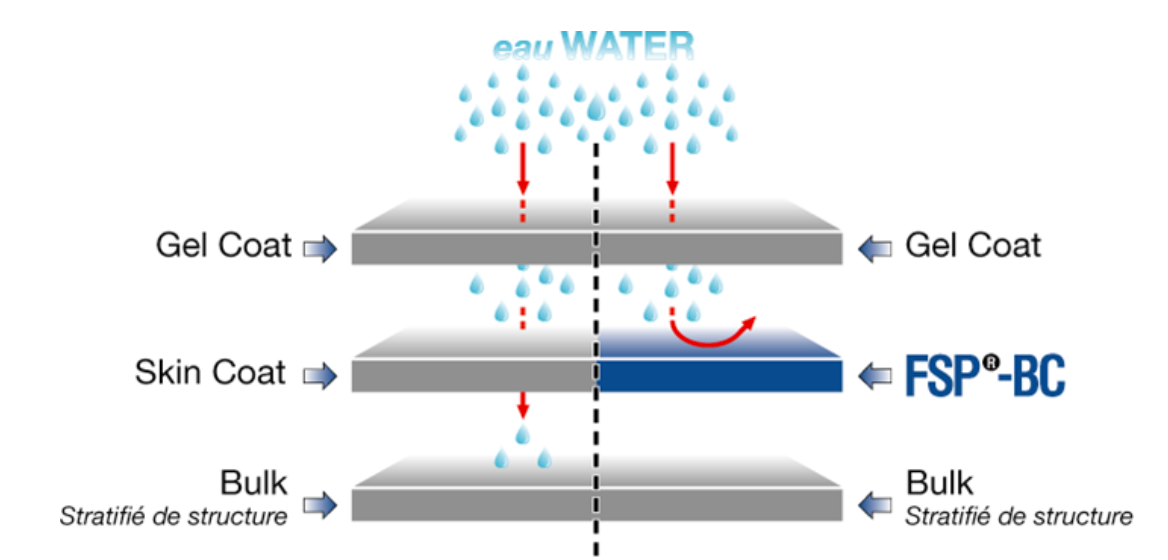

Advantages

- Much less water penetration than with a skin coat ( thin mat with only resin )

- Catalyst revelator

- Good thixotropy, enabling to apply 600 microns in verticalwithout sagging.

- Easy to use.

- Reduces fiber marking

- Improves osmosis resistance

- Reduces porosity risks

- Reduces pre-release risks

- Eliminate risks of elephant skin

Storage Condition

Product should be kept away from direct sunshine and at temperature below 20°C. Under these conditions, the product will keep its properties 4 months from production date.

The information contained in this technical data sheet reflects our current knowledge. It aims at providing information about the application possibilities.