PRODUCT PROPERTIES AND RANGE OF APPLICATION

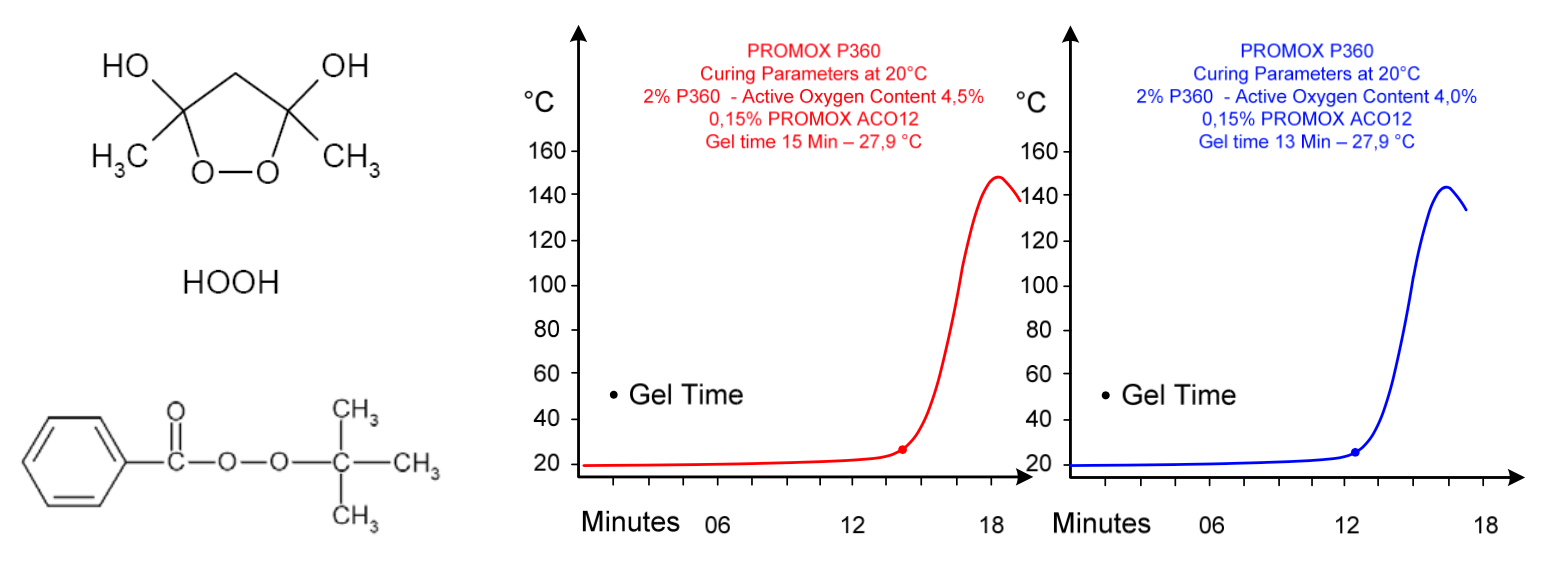

Description of the Products: The PROMOX P360 is a peroxide mixture which contains AcetylAcetone Peroxide (Cas n°. 37187-22-7) and Tert-butyl Perbenzoate (Cas n°. 614-45-9), P360 is AAP with improved cure performances. It is used for the curing process of unsaturated polyester resins together with various accelerating systems. It’s a special mixture based on AcetylAcetone peroxide with energized characteristics of curing.

The PROMOX P360 is a special mixture of peroxides used in most production cycles at a ambient temperature (Polyester concrete and Marble) both at elevated temperature. The concentration of use generally ranges from 1 to 2 part /100 parts of resin.

Accelerators and Promoters: Generally cobalt salts (octoate, naphtenate) are used but seldom vanadium o manganese salts. The accelerator performances can be improved by adding promoters which exalt their action.

Uses and Contraindications: It is a extremely efficient curing agent, especially formulated for the curing of Unsaturated polyester resins at elevated temperatures in union with accelerators like Cobalt (Max 1% in cobalt) salts. It is employed in any case elevated speeds of hardening are required. In comparison to the standards MEKPs the PROMOX P360 underlines elevated speeds of hardening without modifying the gel time. The P360 is a P300 based mixture optimized especially for elevated temperature working cycles. These characteristics make it fit to Filament Winding process, Continuous Laminating process, Resin Transfer Molding process, and Centrifugal casting process.

Employment Area: Polyester Resins, Unsaturated Polyesters, UP Resins. High and Elevated temperature Applications: Continuous Laminating, Fiberglass Reinforced Plastics, Polymer Concrete/Marble, Resin Transfer Molding, Thermoset Composites.

Packaging: Promox peroxides are normally packaged in 25 kg polyethylene drums. Smaller packaging is available as requested. Drums are palletised from 600 to 900 Kg weight net.

Stability: The product is stable under normal storage conditions for at least six months from the date of production.

Storage: When the product is stored under recommended storage conditions, it keeps the original properties for a period of at least six months after delivery. Recommended storage Temperature: < 30°C.

Curing Diagrams and Curing Data: A high reactive, pre accelerated orthophtalic resin has been used to test the peroxide. The Gel time at 20°C is obtained adding 1 parts of peroxide /100 parts of resin and 1 parts of accelerator (Cobalt 1%) /100 parts of resin. Gel time about 18 Minutes.

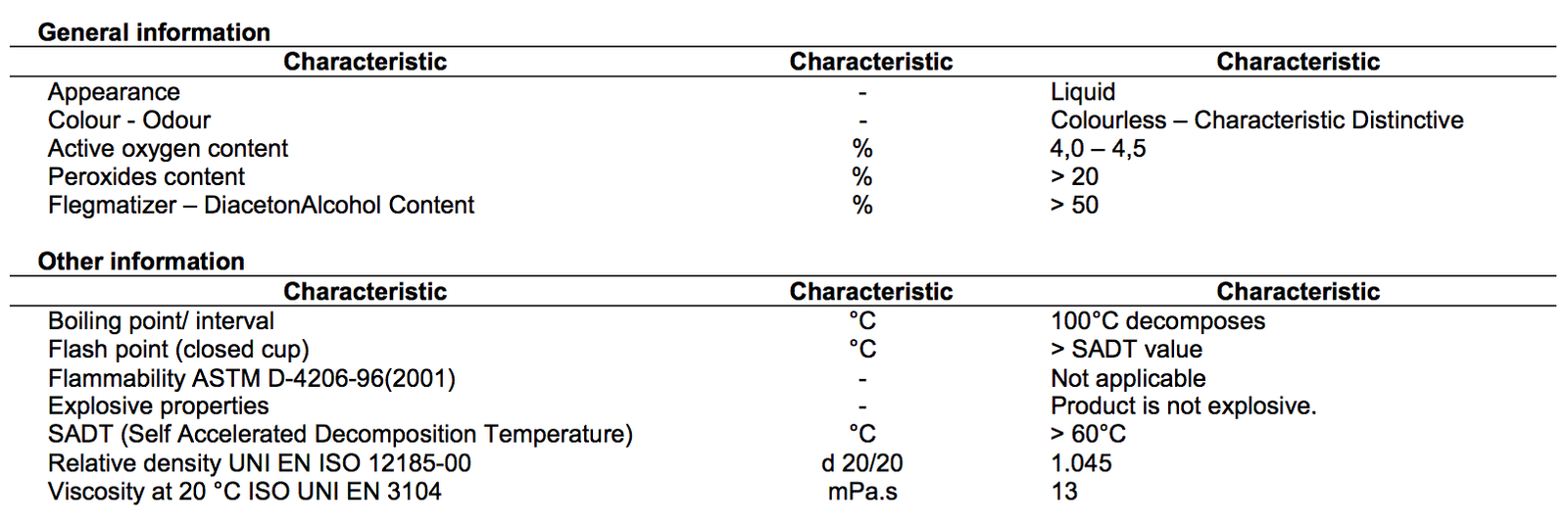

PHYSICAL AND CHEMICAL PROPERTIES