Product Features

- Good conformability

- Good wet-through and fast wet-out in resins, rapid air lease, reducing rolling out time and increasing productivity

- Low resin consumption

- High mechanical strength of parts

- Superior acid corrosion resistance

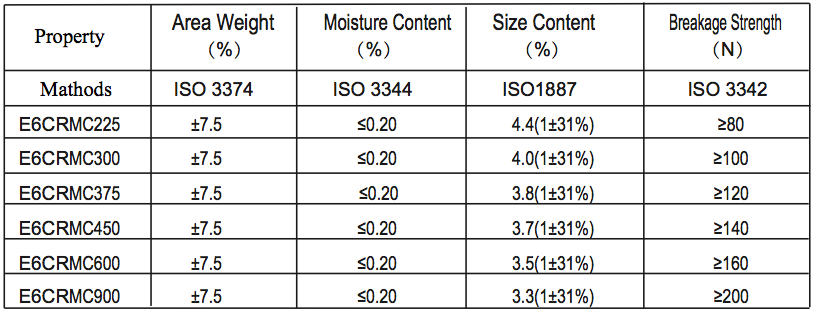

Product Specifications

Storage

Unless otherwise specified, powder chopped strand mats should be stored in a cool, dry, water-proof area. It is recommended that the room temperature and humidity be always maintained at 15°C to 35°C and 35% to 65% respectively.

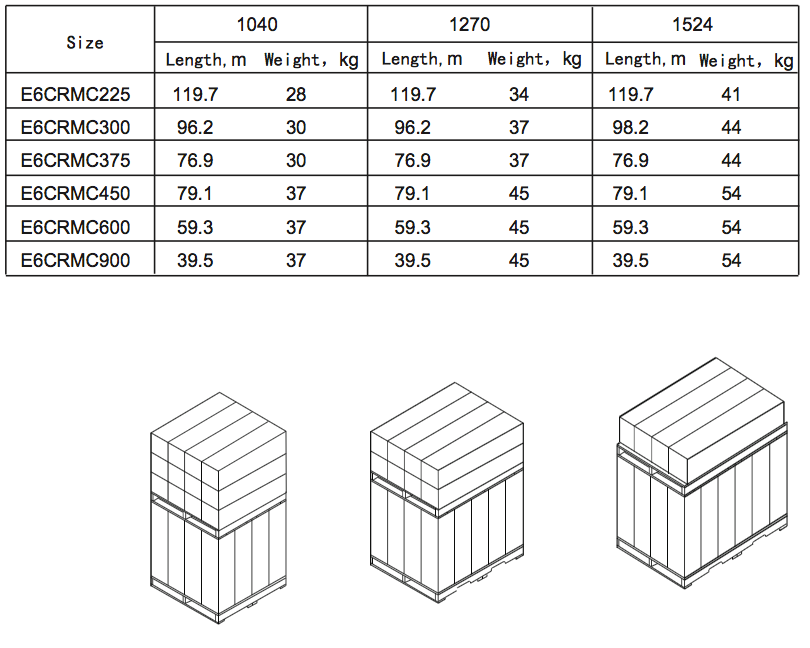

Packaging

Each Emulsion Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 90mm. The roll outside diameter is approximately 265mm. Each roll is wrapped up in plastic film and then packed in a cardboard box. The rolls are stacked horizontally or vertically onto pallets. All pallets are stretch wrapped and strapped to maintain stability during transport.

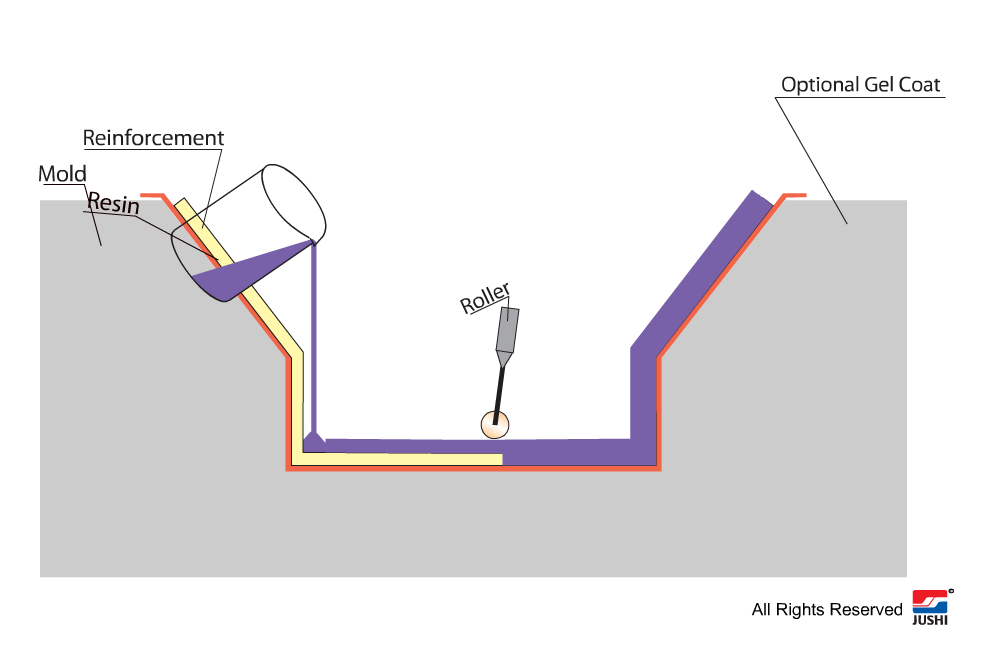

Hand Lay-up Process

Hand Lay-up is an open molding process.

Hand Lay-up is an open molding process.

The reinforcement, in form of fiberglass strands, mat, or woven roving, is first laid into a mold which has been coated with a release agent and a gel coat. Then a resin mix is applied by hand, using a brush or spray gun. A roller is then used to ensure uniform impregnation, complete wet-out and removal of any trapped air bubbles.